Recently, I, along with

many others, attended the Midwest Rep-Rap festival, or MRRF. This

festival is a meeting of hundreds of makers and 3D printing

enthusiasts to talk about and share the latest in 3D printing

technology. I live close, only about 1.5 hours away, but many drive

upwards of 10 hours or even fly to come to this festival. I consider myself lucky.

The festival itself is

held in Elkhart County fair grounds located in a small town nearby called Ligonier. The entire thing was crowded, making it hard to walk

without running into nerds and enthusiasts swapping ideas. It is a

great place to meet people and share tech.

|

| Although the grounds were quite large, the event itself was only held in the buildings in the top left corner |

I set up a booth, but I

had to situate myself in the overflow building, which was also packed

to capacity because I came in later. This is a mistake I hope to

avoid next year. Some people who arrived later than I did couldn't

even find a spot, so they had to set up in some pretty creative

places. I observed one person set his printer on a concession stand

ledge and another set his up on a folding table outside and under the awning. I hope they plan to reserve more buildings the next time

around; this thing is exploding in size.

|

| This guy could not find a space, but it did not deter him for long |

For my booth, I brought

my leadscrew delta and my filament recycling setup for showcasing. I

also brought some other smaller finished projects like my Nerf

blaster, the Mayor. For me, the biggest hit seemed to be the

recycler, namely the shredder. People know about filament extruders

and winders, but shredding documentation is pretty unheard of, so

people where interested in the method I provided.

|

| my printer and filastruder |

|

| my shredder, winder, and Nerf blaster |

Enough talk about me,

there where many other booths, each with their own story to tell. For

the majority of the time, I toured around to see what others had to

offer and left my table unattended. I wish I could have stayed and

told others what I was doing, but I had to see what they were doing

as well. I started with the overflow building, as that was the one I

was situated in.

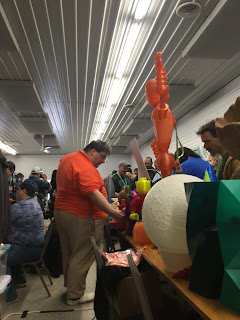

Right next to me, there

was a man in an orange shirt (I did not catch his name, but he was

interviewed several times throughout the day, so I can assume he has

some prestige) who had an entire table (and then some) filled to the

brim with 3D printed sculptures and figures. Sure, they were

impressive and most likely cost many hours and lots of filament to produce, but

anyone could do what they did with a nice printer and several kilos

of filament. Because of this, I did not look thoroughly at his

offerings.

|

| Lots of prints, but anyone could do that. |

Also off our row was a

man who had a paste extruding printer printing in ceramics (and an

accompanying kiln to harden the prints), a person who had produced an

ultra-smart connect-4 board (I played and I lost), and someone with

a very tall printer made from smooth rods (that was broken upon

arrival, a pity as that machine was very neat).

|

| I lost |

|

| this extrudes paste |

One booth had an army

printrbots pumping out parts of plastic. They brought 5 out of the 15

of that type of printer that they had. I asked the owners why they

had all these printers, and they talked about a very interesting

project they do with machines like these. This company takes bulk

orders of cheap/broken 3D printers (this explains all the printrbots,

which went out of buisness in 2018), fixes them up, and then donates

or sells them at discount to other non-profit companies in need of a

printer. I find that quite interesting.

|

| a fleet of printrbots |

Almost completely 3D

printed 3D printers were also common this year. I saw a

Snappy, a

Mulbot, and 2 others made with plastic rods bearing a

resemblance to aluminum extrusion. Those printers were made with

gantries using commonplace household or plastic parts that almost

anyone could produce without ordering online or running to the store.

One of the printers used BBs as a form of bearing, and another used

outright plastic, both producing considerable results.

|

| Snappy |

|

| Mulbot |

Past the extreme

bottleneck of crowds and across the cold and overcast parking lot was

the main building which was just as, if not more crowded than the

overflow building. The large area off to the east housed most of the

sponsors and companies, though a few of the more famous people took

up residence here as well. I spotted a concrete printer sitting next

to the wall that had printed MRRF in concrete on what resembled

welcome mats. SeeMeCNC (the company located closest to the event and

probably the largest sponsor) had their newest line of deltas

sitting up for view along with the legendary PartDaddy, a 2 story

tall plus sized delta printer capable of printing a life-sized

mannequin.

I have had the

opportunity to talk to Steve Wygant several years back when I took

a tour of his facilities and he had said that they were actually able

to scan and print his son with the mega machine (he son could be seen

on display, wearing a hard hat).

This area was by far the most

crowded of the event, and things were packed so tight, one could

scarcely move. For this reason, I could not talk to many of the

booths here. Moving back, I found several other things of interest,

including the owner of the backpack printer, Mitch Cerroni. He could be seen

this (and last, for that matter) year roaming the event with a small

delta strapped to his back. He was able to control it with a tablet

he kept on his person. His thingiverse page can be found

here.

The booth next to him had several fully 3D printed arcade

consoles that were coded with retro favorites for spectators to play.

A long printer was located next to that, and finally, a large alien

that was assembled from the efforts of multiple printers each

printing a chuck that was glued together inside. The UFO the alien

is supposed to be sitting on was in fact so large, that it could not

be assembled within the building.

|

| This alien is truly large. |

Somebody brought a very

impressive SCARA printer on wheels, meaning it had an unlimited Y

axis, but they did not have it working at the time of the event.

(they also showed up late, so they snagged a seat sharing a table

with a woman who made figurines near the sign-in desk).

Unlimited build area

printers are popular this year with the total coming in at 4

including the SCARA mentioned earlier. Two were large and

professional, owned by the company that had them printing little

"business cards" in an assembly line. The other machine was

the same one I saw last year, a prototype printrbot that was small

and looked to be a promising kit build (until printrbot went out of

buisness, RIP). I did not meet him this year, but I met the inventor

of that printer last year, and he is very smart with this technology.

This man worked for Polar3D for a short time before he branched off

on his own. He showed me some of his prototypes that, today, can be

found on popular consumer websites like amazon or eBay.

|

| a great little machine, one of the first of its kind |

|

| One of the two larger printers. The other one looks the same as this one |

Moving up the line, I

talked with a company who creates a filament drying solution for 3D

printers, and to demonstrate, had a roll of filament submerged in a

tank of water feeding a printer that was producing very decent

results. (filament that has taken on water from the atmosphere, or,

in this case, a tank of fluid degrade in print quality, producing

stringing and bubbling) I question this, though. I do not know how

long he had the roll submerged in the tank, so the filament may in

fact not be very wet at all (it takes some time for a filament spool

to become "wet").

|

| the red and blue bricks are supposed to "dry" the filament, but is it wet to begin with? |

Somebody else had an Ultimaker printing drooloops, a type of programmed drooping overhang

that adds an interesting, more sculpted feel of the model it is a

part of. They had a chess set with jellyfish made with this method on

display.

|

| an ultimaker pumping out little flowers for guests to take with them |

Lithopanes are a popular

3D printed artwork as well, but one table had taken it to the next

level with

full color versions. They look like regular lithopanes

when sitting in standard lighting, but when illuminated from behind,

they light up in full color photographs. The biggest beauty of all

this was that the lithopanes were printed with only 3 colors, despite

depicting many.

|

| an all color lithopane |

Somebody else brought a

floor to ceiling delta printer, but what made this machine unique to

others was that it could raise and lower its build platform on

demand. Depending on how big the print needed to be, the bed could be

raised halfway up the printer instead of being situated on the

bottom. I asked the creator the practicality of this, and he said he

made it "because I had the spare parts and I did not want to

reach down to pull a print off". Despite its lazy intentions,

this printer had some serious engineering done on it to make it work

and because of that, I find it very unique.

|

| The delta has its platform currently in the "down" position in this photo |

Some other man had on

display a collection of AIs, or audio animatronics. The Disney

puppet-esque figures sang and danced to a song, and an example

version sat out along with controls for observers to control one of

the puppets themselves.

|

| the tiki pillar sings and dances |

Something else that

struck me were some of the younger makers at the festival, too. Luke

Cunningham (as it states on his convenient business card,

Link) was set up

in the west end of the building with several printers that he

apparently built himself, despite checking in at the ripe old age of

16. He had produced an extended version of what I identified as a Bukito (by Bukobot) styled machine or some variant with a uniquely long build area.

He also showcased an E-waste 3D printer, a machine made almost

entirely out of discarded computer parts. I found this especially

interesting, as I, myself had attempted to produce one of these

machines, only to put it on one of my many back burners after one of

the over-stressed mini-steppers burnt out (this encounter, however,

has reignited my want to finish that project, which I will be doing

soon).

|

| an e-waste printer made of old PC parts |

|

| an extended printer |

Multi-extrusion was more

common this year as well, with many people having filament splicers

like the Pallette, or having machines with multiple toolheads. Many

had 4 or 5 different docked heads that the printer would then change

between depending on what color/material it needed to print with. I

even spotted a plotter that also utilized this method to switch

between pens for a plot. The most unique multi-extruder printer was

one that had about 4 or 5 (I forget the exact number, but it was

many) extruders mounted on a swiveling carousel. A servo motor rotated

it to get the material it needed for a specific section of the print.

Results were stringy, but otherwise good.

During the festival, I

spotted some of the more prominent figures from my other hobby, Nerf,

roaming the grounds. There even was a Nerf table in which nothing was

being done but the modification of nerf blasters. Several Caliburns,

pigeons, jupiters, and the like also littered the table.

|

| messy with Nerf modification |

|

| people were working on blasters here during the festival, too |

Jesse Kovarovics, the man

behind FDL was also there with a booth in my building showcasing his

newest 3D printed blasters. I took this opportunity to have a pro critique my work and showed him my blaster for his opinion. Much to my surprise, the face

of Nerf, Drac (his alias, not real name) showed up there as well. I

managed to snag a picture of him holding my work, too (for publicity's

sake, of course ;). This just goes to show how closely tied together

these two hobbies are, and it is no mystery why 3D printing got me

into Nerf as well.

|

| some of the FDL blasters |

|

| Jesse gives my interpretation a once-over. |

Throughout the day, I

continued to roam the buildings, taking looks at all that was

offered, also taking frequent brakes back at my booth to explain what

I was doing there as well. I took too many pictures to explain them

all, so I will put them below for you to look over. I had much fun at

this festival, and am already making preparations for next time.

|

| I love crowd shots. They really capture a lot. |

|

| another shot of the Nerf table |

|

| Don't know why one would need a spool this big, but it is as cool as [insert comparison here]. |

|

| A plotter makes R2-D2 |

|

| strange servo controlled tentacle |

|

| cement delta printer |

|

| tall |

|

| multi-tool plotter |

|

| this printer prints big and small (see the top of the cup) |

|

| these guys made everything here, including the table |

|

| crowd shot! |

|

| wall of sponsors |

|

| one of the PartDady vases |

|

| 3D printed V-slots |

|

| Same with this one. |

|

| a Pallette merging system |

|

| small printers really appeal to me |

|

this guy wore a strange stick costume all day to

promote his 3D printed robot structure method |

|

| yet another crowd shot |

|

| Of course the day wouldn't be complete without a drive-by snap of Joel |

The complete gallery (including some ding photos) can be found

here

Recently, I, along with

many others, attended the Midwest Rep-Rap festival, or MRRF. This

festival is a meeting of hundreds of makers and 3D printing

enthusiasts to talk about and share the latest in 3D printing

technology. I live close, only about 1.5 hours away, but many drive

upwards of 10 hours or even fly to come to this festival. I consider myself lucky.

Recently, I, along with

many others, attended the Midwest Rep-Rap festival, or MRRF. This

festival is a meeting of hundreds of makers and 3D printing

enthusiasts to talk about and share the latest in 3D printing

technology. I live close, only about 1.5 hours away, but many drive

upwards of 10 hours or even fly to come to this festival. I consider myself lucky.